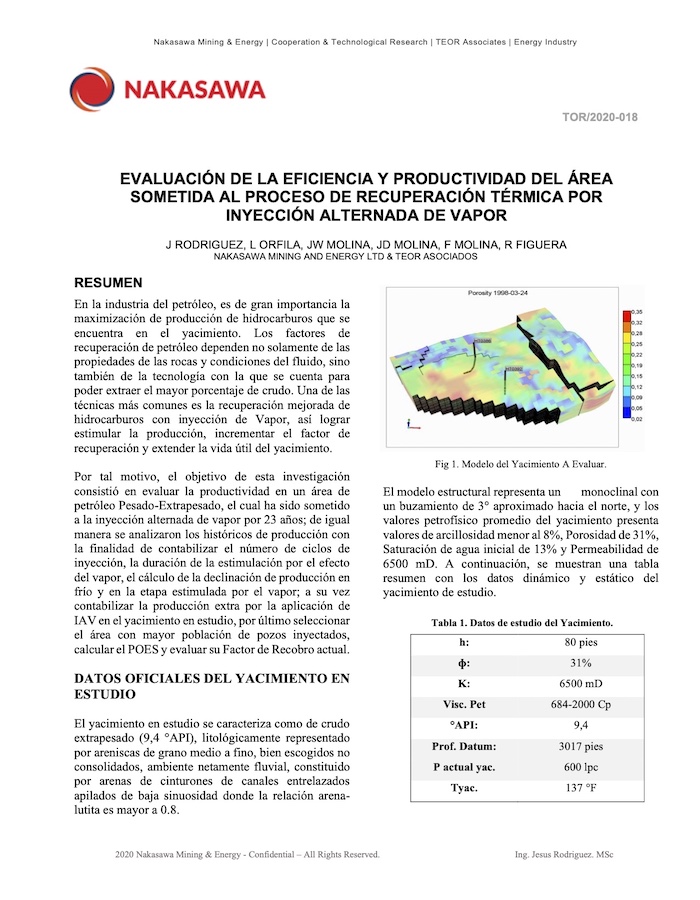

EFICIENCIA Y PRODUCTIVIDAD DE RECUPERACIÓN TÉRMICA POR INYECCIÓN ALTERNADA DE VAPOR

Oil is considered the most important fuel for energy and transportation needs around the globe, so enhanced oil recovery vs fracking is a hot topic of conversation for oil industry investors.

In the United States, oil fields tapped out by conventional drilling methods are still laden with extensive amounts of oil trapped in the shale. Producing more oil output could only be achieved with innovative techniques to release this trapped oil from existing wells.

Fracking has been used for years to extract the hard to reach oil and enhanced oil recovery (EOR) is quickly becoming a promising route for producing more oil output than fracking.

Fracking uses water and chemicals forced into rock formations under high pressure to crack the rock, release the trapped oil, and push it to the surface.

Fracking has proven to be a huge success that has brought the price of petroleum and resulting petroleum products down.

The fracking industry has become cost-effective for delivering higher outputs of oil. However, many critics question the extreme water usage and environmental pollution associated with fracking.

The enhanced recovery idea has been around a long time but was not financially viable until now.

EOR encompasses the newest techniques used in the oil industry for producing more oil output by using methods such as pumping carbon dioxide (CO2) into existing oil wells to release trapped oil from rock formations and extend well productivity.

The CO2 acts like a lubricant and releases an impressive amount of oil that even fracking can’t reach. Oil fields in New Mexico and Texas are currently profiting from this method, with plans to tap existing fields across the country soon.

The benefits of enhanced oil recovery vs fracking are the highlight of the use of steam, CO2, water, or other fluids instead of a chemical/water mixture to release trapped oil.

Existing oil well projects as well as the production skyrockets, sometimes bringing up more oil than during initial drilling.

CO2-based EOR is a preferred method that offers the reward of trapping CO2 underground during the process. Reducing CO2 levels from our air and sealing it within the earth’s surface keeps global-warming activists quiet.

Another enhanced recovery process is the use of de-watering technology that turns water soaked oil into the clean water for human or agricultural use, lowering industry pollution further.

EOR could produce up to 4 million additional barrels per day in the United States alone. As the use of these new oil recovery methods spread, more output is expected to add to our crude oil reserves.

The success of fracking will keep it in favor for many years, but the overall lessened environmental impact paired with heightened oil recovery will make enhanced oil recovery solutions a favorite as their benefits outperform traditional fracking methods.

In the recent past, oil companies have increasingly produced heavy oil. As a matter of fact, it is estimated that about 70% of the current remaining reserves are being drilled for oil exploration. However, heavy oil is also becoming abundant, and its thick—like tar has also become difficult to extract. This brings to light the use and application of Enhanced Oil Recovery (EOR) generators and their drilling methods.

Enhanced Oil Recovery is an oil extracting method where steam is injected into the oil reservoirs hence making it easier for a pump to pump the oil to the surface. Unlike other oil extracting methods, EOR is more advanced. The notion behind this argument is based on the fact that it becomes easier for oil drilling companies to extract quality crude oil.

As a way of enhancing a compelling production of oil, generators used in EOR are usually connected to a feed water system, power supply, and fuel supply. The following are some of the advantages of using EOR as compared to other oil extracting methods.

The EOR system uses steam to enhance oil production. Thanks to this steam injection, well productivity is boosted to levels of up to 300%. This, in turn, correlates to an increase in oil production from wells that could have produced a low level of oil. Apart from this, EOR can extract about 30% to 60% of more oil reserve as compared to 30% extracted using both primary and secondary oil recovery methods.

A significant advantage of EOR is the fact that it used to extract oil from areas that would have been hard to extract in the first place. With this in mind, more oil is extracted, which correlates to an increase in capital.

It is estimated that onshore enhanced oil recovery process pays about $10-16 per ton of the CO2 injected for oil prices in ranges of $15-20 per barrel. This indicates an increase in oil production at pocket-friendly prices. Apart from this, there is a clear indication that high levels of oil recovery are achieved while drilling and production costs are kept at low levels.

Enhanced oil recovery steam generators have a high total of dissolved contents and handle zero hardness of feed water.

EOR steam generators have the greatest rates of success in an estimated 70% of the total heavy oil fields globally. This is a clear indication that more drilling companies are dependent on EOR as compared to other oil drilling methods and generators.

EOR steam generators are easy to set up, as well as load drilling, and steaming cycles. The underlying advantage is the fact that it becomes easy and faster for companies to extract more oil while maintaining simplified cycles and achieving high-end results.

EOR steam generators operate on gas. With an EOR generator, it is estimated that up to 80% of gas is saved as compared to using other methods of oil extraction. The saved gas can be used in high-value applications such as in electricity generation, industrial development, desalination, and its exportation as LPG.

Enhanced oil recovery generators have a zero emission of carbon monoxide and nitrogen oxide associated with fuel combustion. The quality of air in areas where EOR generators are used are well maintained as compared to areas where other methods of oil drilling are used. This, on the other hand, indicates a low level of pollution, and a reduction in global warming associated with air pollution.

Steam flooding, or steam injection, is a crude oil extraction method, where steam generated at the surface is directly injected into an oil reservoir via evenly distributed wells. When the steam enters the oil reservoir, it heats the crude oil hence reducing its viscosity. EOR generators simplify the steam flooding process as well as promote cyclic steam stimulation. This, in turn, enhances the production of oil.

Since EOR generators transport carbon dioxide through underground pipelines, the extent at which land is used is reduced. The underlying advantage of using underground pipes to transport carbon dioxide is the fact that instances of environmental destruction are reduced. Apart from this, land that could have been occupied by the pipes is used to support generators and the drilling company in general.