CHALLENGE

Nakasawa Resources’ innovative ultrafiltration (UF) technology provides clean, purified water. Our UF system has been designed and manufactured to replace several processes, enhancing efficiency and decreasing downtime. These systems translate into improved feedwater treatment, allowing for better performance and a longer life for steam generators.

OUR SOLUTION

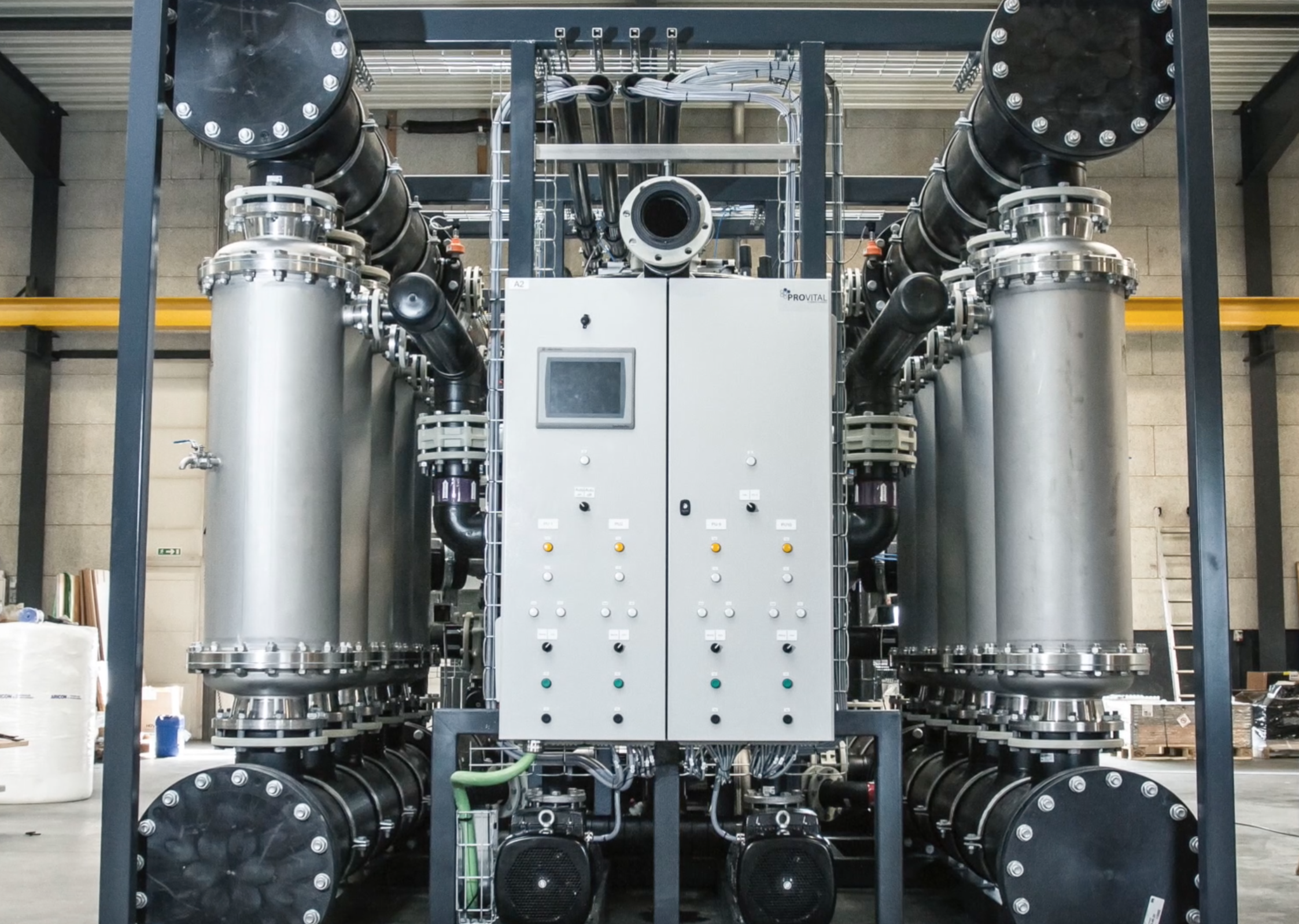

Nakasawa Resources’ innovative ultrafiltration (UF) technology has been designed and manufactured to provide clean, purified water. It replaces several processes to enhance efficiency and decreases downtime.

Industrial units are manufactured with different types of ceramic membranes, using a unique and innovative new technology: Selective silicon carbide (SiC) layers with different pore sizes. This ensures a high-performance liquid filtration and gas cleaning process.

Ceramic membranes remove sediments, oils, suspended solids, metal oxides, and dissolved organic matter.

100%

OF OILS AND SUSPENDED SOLIDS REMOVED

75%

LESS ENERGY USED WHEN COMPARED TO ANY OTHER MEMBRANE TECHNOLOGY

100%

OF WATER PRODUCED BY OIL AND GAS PRODUCTION DISCHARGED AND REINJECTED

PROCESS

First, water enters the system through the feed line, where it is then directed to the feed pump. Next, water is pumped into the system, passing through the flow and pressure sensors before flowing to the circulator.

Afterward, water is pumped through the ceramic membranes and separated into two streams: Clean water, called “permeate” that passed through the membranes, and contaminated water, which has solids and solutes of high molecular weight. This contaminated water, called “retentate,” is then expelled from the system. The permeate that flows through the membranes then passes through the permeate pressure transmitters.

Finally, the permeate continues through the adjustable permeate valves to reach the permeate and backwash tank, where it leaves the unit through the permeate outlet point. This process produces purified water for steam generation. The two main ultrafiltration systems processes are:

1. Dead-end filtration (barge-mounted system)

2. Cross-flow filtration (continuous process)